(noon – promoted by ek hornbeck)

Greetings folks, welcome to another edition of Manufacturing Monday. Sorry about last week, it’s normally my goal to have a new edition out on the first day of the week, but sometimes life can be unpredictable and throw you a curve ball. Well, several interesting things this week ranging from manufacturing information

about computerized systems activity to California looking to gain Tesla’s plants. Plus the Financial Times reports on China dethroning the US from it’s Manufacturing title.

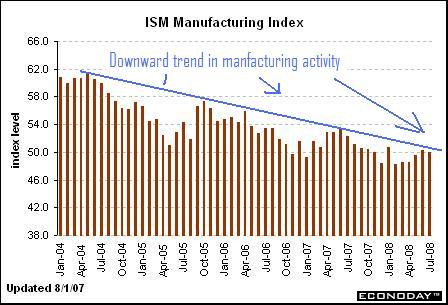

US Manufacturing feeling kinda “meh”

Last week we got in several important economic numbers in regards to our subject at hand. Manufacturing activity as reported by the Institute of Supply Management, gave a number of an even 50. Not exactly great news here, as the previous month, the ISM number was 50.2. Any number above the big five-oh means expansion in manufacturing, whereas below it is the opposite. But what about 50? Let’s just say “meh”, not good, but not too shabby either, could be better. Folks had their estimates as high as 53.5, so disappointment was making the rounds.

We then had the Factory Orders, which represent orders for durable and not durable goods, increased 1.7% for the month of June from May. This confirms the previous ISM number of 50.2. So if ISM was a leading indicator, perhaps we may see a drop in factory orders for the month of June?

Lastly, we’ve labor costs and productivity figures for the second quarter. Economists were expecting productivity increases between 2 to 3%. The first quarter showed an increase of 2.7% Well for the second quarter, we saw an increase of 2.2%. So once again, businesses are squeezing more out of workers, but what about the cost of labor? In the previous quarter, unit labor costs, which to you social conservatives out there means how much does it cost to hire a worker to produce one unit of something, increased 2.2%. This time around, though, we saw 1.3% growth in the cost of unit labor for the quarter. Sorta in the middle of what others were expecting which was an actual shrinkage of 1.3% to an increase 2.0%.

So what the hell does this all mean? We’ve industrial activity in neutral from a past increase that was verified with those factory orders numbers. For employers, productivity is still outpacing their costs of labor, which is a plus for industrial growth for the nation. But for workers, who face their own inflationary costs, are facing the prospect of lower earnings. If next month’s report on factory orders confirms the ISM numbers, then we may be seeing a slowdown even in manufacturing. Manufacturing, while we’re seeing some growth (and acknowledgment that “Made in the USA” could be back), it is anemic. Indeed, there are still factories shedding jobs in many parts of the country, let alone the woes of the automakers. This all adds up to what Bondad has been saying recently, that we’re still in a recession.

San Jose wants to be the green Motor City

San Jose is on the short list of possible manufacturing sites for Tesla Motors Inc.

The city’s economic development staff is in talks with the electric automaker, which revealed plans in June to build the manufacturing facility for its four-door sedan close to the company’s San Carlos headquarters. Tesla is considering “a handful of cities” in the Bay Area, according to a staff report from the city.

Tesla plans to begin production of the sedan in late 2010.

City officials say the Tesla plant is in line with San Jose’s green vision for the city, which includes goals such as creating 25,000 cleantech jobs in 15 years.

– excerpt from “San Jose in talks about Tesla Motors manufacturing site“, San Jose Business Journal, 2008

The rise and fall of the “Big 3” (soon possibly to be the Domestic Duo) could also mean a change in identification of the auto industry. Where in the past, Detroit was synonymous with the automobile industry, it seems that new metropolitan areas are looking to take up that mantle. Now that isn’t to say that Motown will lose it’s title, I mean who knows Ford and GM could come back (and possibly Chrysler too). But when it comes to the new era of green automotive manufacturing, old Detroit is having a hard time playing catch up. And it seems as if San Jose is looking to take that brass ring.

Tesla Motors, the company in question, is already located in San Carlos, which is half way between San Francisco and San Jose. The company produces a line of battery-powered sports cars dubbed the Tesla Roadster. The zero-emission cars were originally assembled in the UK in partnership with Hethel-based Lotus Cars; with parts spanning the globe, but has since concentrated production lines in California. Tesla Motors has plans on producing a sedan in 2010 as well. So far, sales have outstripped manufacturing capacity. So it is no surprise that there is talk of expansion, and I’m glad that they’ve decided to focus on North America.

“It was kind of a no-brain decision for us,” said Darryl Siry, the company’s senior vice president of global sales, marketing and service. “A major reason was to avoid the transportation costs, which are terrible.”

– excerpt from “Shipping Costs Start to Crimp Globalization “, New York Times, 2008

– Additional credit goes towards Alex Steffen at Worldchanging.com for first pointing it out.

So is world trade turning in on itself because of fuel and carbon?

That seems to be the jist of two very interesting pieces I’ve read this past 24 hours. The first came to me from the good folks at Worldchanging.com, an article by Alex Steffen, in which they site an additional piece from the New York Times (think of that as a double header, wow, two for the price of one!). The second article comes from Industry week, by Dr. Joe Thomas, the Dean of Cornell University’s School of Management.

Both articles hit on one similar theme that being fuel costs, yet the Steffen article actually takes on two new angles. The prices of fuel has been skyrocketing and thus decreasing the profit margin of importers, something we here have said in the past. Indeed, though the price of crude has been coming down recently and could go down further, this situation may not last long. Long term fundamentals still suggest $200 oil, and if in doubt, please refer to Jerome a Paris’ series on the subject.

Aug. 8, 2008 — The higher oil prices that have shocked American industry and consumers alike may contain more than a silver lining, they present a golden opportunity to propel the U.S. into a more productive and efficient future. The short-term pain of higher transportation costs will turn into long-term gains if national policy aims forward instead of backward.

Both presidential candidates have addressed this issue mostly in response to higher gas prices for consumers. But the responses so far — more offshore drilling and conservation — address only part of the problem. A national policy based on alternative energy, natural gas, better mass transportation, more stringent auto mileage standards, tax breaks for greener technologies and offshore drilling (although results will be years in the future) and nuclear energy will be necessary to power up industry and consumers.

– excerpt from “Viewpoint — High Oil Prices Could Help U.S. Manufacturing“, Industry Week, 2008

As previously mentioned, Steffens though takes on two new angles beyond what Thomas sees. Whereas Thomas, rightly sees green manufacturing potential in relations to fuel costs, Steffens takes a derivative of that notion. That derivative being carbon footprint costs. Carbon trading is a reality now in Europe and soon the US. Eventually, the cost of pollution will reach the consumer unless there is an offest of some sort.

*Far-flung supply chains may drop costs (even with higher oil prices), but the multiply climate change emissions. That already presents a marketing challenge as consumers grow more aware of their carbon footprints. And if political consensus emerges on pricing carbon (as seems likely), some of the price advantages of global complexity could vanish overnight.

– excerpt from “Could Globalization Be Going In Reverse?“, Worldchanging.com, 2008

The second dynamic that is touched on is political and social climate situation. Political instability has always been with us, but for globalization’s industrial plantation owners, it’s been stable enough to make a quick but. Not so more, Steffens says, as what held up the crony capitalism in the past is quickly rotting itself out. On top of this, globalization has given us a new threat, a potential pandemic for the jet age. Some sort of strange disease is coming, and its got frequent flyer miles!

Globalization suffers from some big disruptive vulnerabilities. An extreme act of terror, say a dirty bomb in a shipping container, could easily bring the whole system screeching to a halt. Ditto bird flu. Same with mass migrations triggered by environmental degradation and climate change in already desperately poor countries. Heck, even the right kind of invasive species scare could put a hiccup in the system, but some of these could stop trade altogether for quite some time.

– – excerpt from “Could Globalization Be Going In Reverse?“, Worldchanging.com, 2008

There was a movie in the 1980s in the UK called Threads, one of those atomic war flicks akin to the Day After, just only way better. The film postulated that what holds up society was actually something very fragile. Steffens is saying the same thing, that companies have stretched themselves with global supply chains that could easily be disrupted by even a minor hiccup.

I highly recommend you take a look at both pieces. Very informational, and frankly I wish many conservatives would read this. The big picture is screaming that the way things are operating can’t be done anymore. Perhaps globalization is now running on fumes. Only time will tell.

China overtakes US in manufacturing

I guess it’s official now, the Financial Times is reporting that China will overtake the United States in manufacturing by next year. Years ahead of schedule according to the press and experts, frankly, I thought this happened already. It’s not surprising really when overseas manufacturing and shipping is much cheaper compared to US manufacturing alone. Additionally, it’s really easy for businesses to uproot their manufacturing plants and send them to China, especially when there are sites like jonble.com which can help them every step of the way. Walk into any retailer, and most of the stuff they sell is stamped with “Made in China.” Now the experts also include health and food processing, you know shampoo and microwave meals, as part of manufacturing. Does this mean we should start expecting this stuff to come from China as well? I once bought a box of fancy crackers at Costco and when I got home it actually said “Made in Hong Kong.” One of those WTF moments, you could say.

China is set to overtake the US next year as the world’s largest producer of manufactured goods, four years earlier than expected, as a result of the rapidly weakening US economy.

The great leap is revealed in forecasts for the Financial Times by Global Insight, a US economics consultancy. According to the estimates, next year China will account for 17 per cent of manufacturing value-added output of $11,783bn and the US will make 16 per cent.

– excerpt from “China to overtake US as largest manufacturer“, Financial Times, 2008

This is sad, really sad, and no not just a pride thing. The green in me knows full well that that increase production is coming from major polluting factories. I know that manufacturing plants in the US aren’t exactly environmentally friendly, but compared to China we’re frackin’ awesome! China talks up green manufacturing, and outside of some “show” plants, it just ain’t happening. Here in the US, we’ve got a long way to go, but at least we’re making strides in green manufacturing.

I’m also sad because that 11 trillion number means money being made their, and not here. I’m sure it isn’t we Americans who feel this way, I’ve talked to Europeans and South Americans who would like to see more stuff made in their countries. That 17 trillion, in my opinion is a lost opportunity. Capital made from that production will be reinvested there, which will have a compounding effect. This could go to spur on more new types of industry or services, and well you get the idea. We could’ve had that 17 trillion, or a good chunk of that here. More good union jobs, more job security, more investment, more tax revenue.

John Engler, president of the National Association of Manufacturers, a Washington-based trade group, played down the effect of the projections. It was “inevitable” that China would take over on account of its size, he said. “This should be a wholesome development for the US, for it promises both political stability for the world’s largest country and continuing opportunities for the US to export to, and invest in, the world’s fastest-growing economy.”

– excerpt from “China to overtake US as largest manufacturer“, Financial Times, 2008

No John, I’m sorry, but it wasn’t inevitable, it was made to happen by people like you. People who own companies that want to produce goods and found that wage arbitrage was the way to go. First it was several companies, then others realized that those first to ship jobs overseas had a cost advantage. Words like “competitive advantage” and phrases like “lose of market share because our costs and prices are higher” started to be echoed about board rooms and trade shows.

How you could label this a “wholesome” development is beyond me. When I see towns, no wait cities, yes cities dying from lack of investment, the only development I see is the rotting of America. You folks, I got to hand it to you, you played up that stability card with the government during the Cold War. The game plan was really easy, convince America to sacrifice jobs so we could employ the workers there and not let the Commies take over. A diabolical version of the Marshall Plan, you could say. Many will hate me for saying this, but I honestly could give a rat’s behind for China’s stability. Not when it comes at the expense of our workforce and economic future. No, Mr. Engler, this isn’t a wholesome development at all, it’s an economic abortion!

Cross posted on

The Economic Populist –

A Community Site for Economics Freaks and Geeks

8 comments

Skip to comment form

Author

Yes, sad to say, it’s Monday already. First let me say thank you for reading the latest edition of Manufacturing Monday. Secondly, I do hope you all have a good upcoming week. Pleasantries aside now, lets go kick some Republican ass!

By the way I have seen the movie “Threads”…..we don’t want an economic equivalenmt of that….

I wish somebody would do a piece about buying American or at least not buying made in china stuff. I was pretty disappionted to find out the Viking immersion blender I was coveting was made there. I figured being Viking there was a chance it was. So. I have my eye on a Swiss one that is pricey and will maybe be a work some overtime gift to my kitchen.

That Tesla motors news I interesting. Pretty small market for those I would suspect but apparently they have opened their first showroom in LA.

Couldn’t agree more about the environmental negatives of China’s manufacturing.

FWIW, I’ve ranted for about 5-7 years to friends and acquaintances (anyone who will listen, basically) that the U.S. ultimately, out of desperation, will go to war with China over China’s poisoning of the planet.

For environmental reasons, I’d rejoice at $10 gas.

its due. I am so glad this place exists. I love orange, but psychedelic eyes are the best.

Maybe it’s doing what it should what it was billed as. So perhaps it’s actually going to ‘sort it out’. Globalism’s only positive offering is that it is a double edged sword and perhaps it will turn the worm.